ARMORED SUBMERSIBLE Power CABLE

페이지 정보

본문

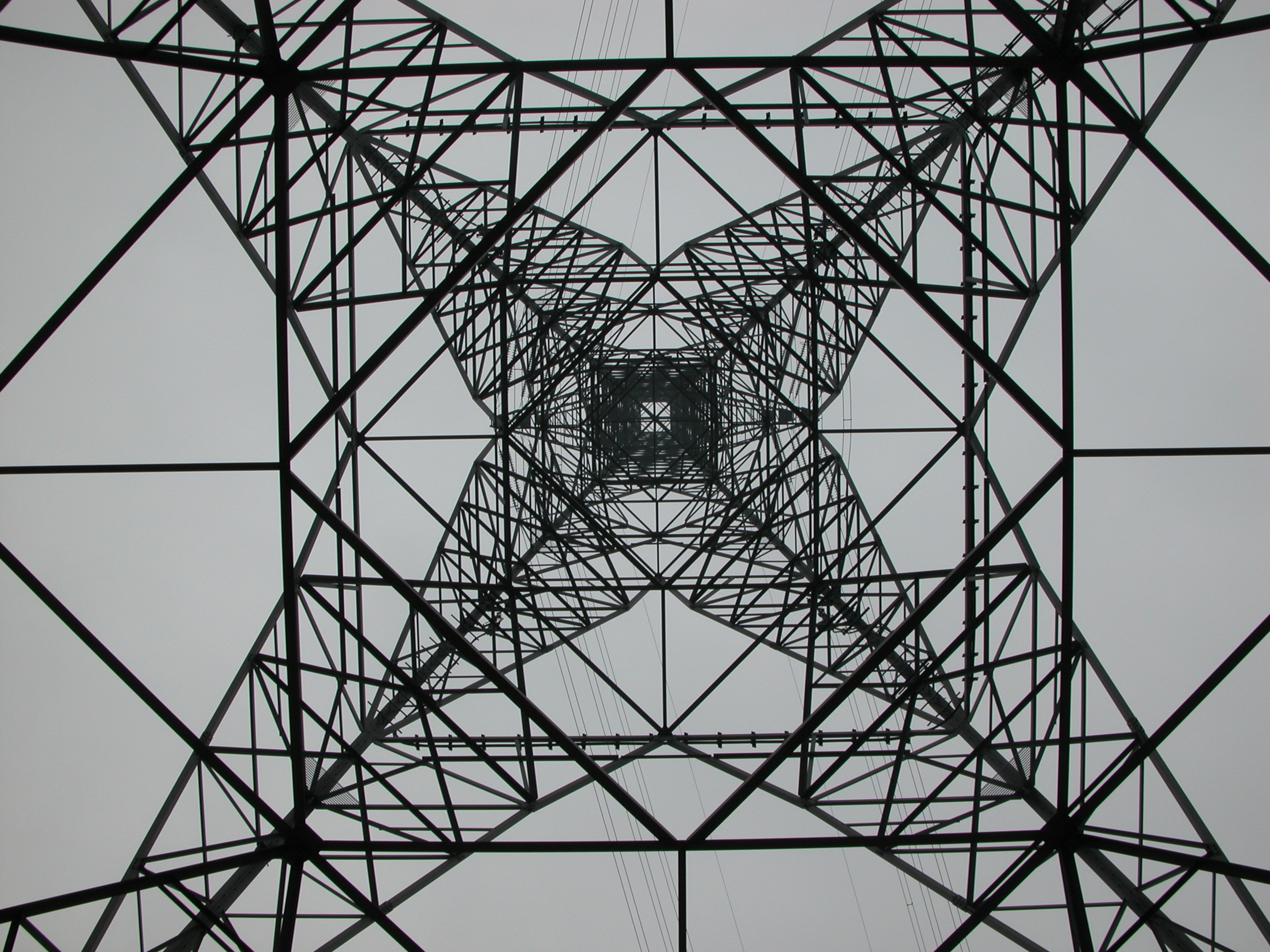

As to the cable armor 480 and 490, metallic or steel alloy could also be employed, optionally in multiple layers for improved injury resistance. Power cables and MLEs that may resist damaging forces, whether or not mechanical, electrical or chemical, can assist guarantee proper operation of a motor, circuitry, sensors, etc. Noting that a faulty power cable (or MLE) can potentially damage a motor, circuitry, sensors, etc. Further, as talked about, an ESP could also be situated several kilometers right into a wellbore. Further, armor indentations on the lead (Pb) were visible, together with indentations with sharp edges; noting that such sharp edges can promote crevice corrosion. The circuitry block 350 could or might not be able to deriving energy from an unbalanced WYE level and, further, might or will not be capable of knowledge transmission via an unbalanced WYE level. As shown, the MLEs 500 connect with a motor block 315, which could also be a motor (or motors) of a pump (e.g., an ESP, and so on.) and be controllable by way of the VSD/step-up transformer block 370. In the example of FIG. 3, the conductors of the MLEs 500 electrically join at a WYE level 325. The circuitry block 350 might derive power via the WYE level 325 and may optionally transmit, obtain or transmit and obtain data by way of the WYE point 325. As proven, the circuitry block 350 may be grounded.

As to the cable jacket 470, it could also be round or as shown in the instance 401, rectangular (e.g., "flat"). In the instance of FIG. 4, the power cable 400 contains three conductor assemblies where every assembly includes a conductor 410, a conductor shield 420, insulation 430, an insulation shield 440, a metallic shield 450, and a number of barrier layers 460. The three conductor assemblies are seated in a cable jacket 470, which is surrounded by a primary layer of armor 480 and a second layer of armor 490. As to the cable jacket 470, it could also be round or as proven in an alternate example 401, rectangular (e.g., "flat"). FIG. 11 shows instance graphics as to some amount of compression and extension of an meeting 1001 with out a cushion layer in comparison with less compression and extension of an meeting 705 with a cushion layer 760. As indicated in FIG. 11, one or more dimensions and/or shapes may be utilized to characterize an amount of deformation of an meeting, significantly an quantity of deformation of a lead (Pb) barrier layer of an meeting. For example, a braid layer can help present protection to a mushy lead jacket throughout an armor wrapping process.

As to the cable jacket 470, it could also be round or as shown in the instance 401, rectangular (e.g., "flat"). In the instance of FIG. 4, the power cable 400 contains three conductor assemblies where every assembly includes a conductor 410, a conductor shield 420, insulation 430, an insulation shield 440, a metallic shield 450, and a number of barrier layers 460. The three conductor assemblies are seated in a cable jacket 470, which is surrounded by a primary layer of armor 480 and a second layer of armor 490. As to the cable jacket 470, it could also be round or as proven in an alternate example 401, rectangular (e.g., "flat"). FIG. 11 shows instance graphics as to some amount of compression and extension of an meeting 1001 with out a cushion layer in comparison with less compression and extension of an meeting 705 with a cushion layer 760. As indicated in FIG. 11, one or more dimensions and/or shapes may be utilized to characterize an amount of deformation of an meeting, significantly an quantity of deformation of a lead (Pb) barrier layer of an meeting. For example, a braid layer can help present protection to a mushy lead jacket throughout an armor wrapping process.

In such an instance, an extruded cushion layer can obtain a desired hoop stress, which may help the extruded cushion layer to retain its form. For example, a die may provide for extruding materials in a substantially tubular form a few lead (Pb) barrier layer. In such an example, an non-obligatory armor layer could also be of a thickness of about 0.5 mm. As an example, a cable can embrace a conductor with a conductor shield that has a radial thickness of approximately 0.010 inch (e.g., roughly 0.254 mm). For instance, the conductor shield 420 could also be supplied as an extruded polymer that penetrates into areas between strands of the stranded conductor 410. As to extrusion of the conductor shield 420, it might optionally be co-extruded or tandem extruded with the insulation 430 (e.g., which may be or include EPDM). As an example, a conductor (e.g., solid or stranded) could also be surrounded by a semiconductive materials layer that acts as a conductor shield where, for instance, the layer has a thickness better than approximately 0.005 inch (e.g., roughly 0.127 mm). In some embodiments, a metallic shield layer might serve to electrically isolate the phases of the cable from each other.

For instance, every conductor meeting part might embody solid metallic tubing, such that splitting out the phases is extra easily completed (e.g., to terminate at a connector, to provide improved cooling, and many others.). For instance, a multiphase power cable can embrace color coded cushion layers where a distinct shade can code every part of the multiphase power cable. In the instance of FIG. 5, the MLE 500 (or "lead extension") a conductor 510, a conductor shield 520, insulation 530, an insulation shield 540 and/or a metallic shield 550, one or more other barrier layers 560, a braid layer 570 and armor 580. While the example of FIG. 5 mentions MLE or "lead extension", it may be implemented as a single conductor meeting cable for a number of of a wide range of downhole uses. In such an example, the respective lead (Pb) barrier layers of the assemblies (see, e.g., the lead (Pb) barrier layer 1050) change into distorted accompanied by some lack of symmetry.

For more info regarding low voltage armored power cable review the web page.

- 이전글비아그라 시알리스 구매-고혈압 치료제 부작용-【pom5.kr】-타다라필 구입 25.01.13

- 다음글The Advanced Guide To Asbestos Mesothelioma Lawyers 25.01.13

댓글목록

등록된 댓글이 없습니다.